Technical Info

If you’re considering increasing your engine’s horsepower, it’s good to understand where horsepower comes from...If you’re considering increasing your engine’s horsepower, it’s good to understand where horsepower comes from. Horsepower is determined using a mathematical equation involving engine torque (measured in foot-pounds) and engine rpm. Because horsepower is directly related to torque, the goal is to increase the engines torque output.

The amount of “down force” that the piston applies to the crankshaft determines torque. There are several ways to increase this. Probably the most obvious is to increase the crankshaft’s stroke. This is accomplished by moving the rod journal farther away from the centerline of the crankshaft. So, you can see that by increasing the stroke, you’re increasing the rod’s leverage on the crank just as you would increase your leverage on a wrench by using a pipe or “cheater bar”.

Another method of increasing the piston’s down force is to create a more powerful burn in the combustion chamber by increasing the pressure in the cylinder. One popular method is to force the air in using a supercharger, hence, forced air induction. Also, adjusting the cam timing will effect cylinder pressure. For example, advancing the cam causes the intake valve to close sooner. Since the piston is coming up on it’s compression stroke at this point, closing the valve sooner will increase cylinder pressure (though this method loses it’s effectiveness at higher rpm).

Increasing the compression ratio will increase cylinder pressure. This can be a very practical way to go. However, you must be very cautious here; too high a compression ratio without the necessary amendments can be fatal to your engine, especially in conjunction with a supercharger. Probably the safest, most efficient and cost effective method of increasing your engine’s cylinder pressure is eliminating the resistance of airflow in the cylinder head and manifolds.

By replacing your stock cylinder head with one which has been professionally ported and tested, and a camshaft that will take advantage of the new head’s potential, you can achieve a horsepower increase through out the rpm range. You may even notice an increase in your fuel economy. Unlike most of the other methods, where you must sacrifice one thing for another, increased airflow equals free horsepower.

Valve Guide Replacement

The valve guide is the heart of the cylinder head. If the wrong material is used or the wrong procedure followed, the valve guide will fail and nothing else will matter. The installation process of the guide is as important as the material the guide is made of. The most common scenario (on domestic cast iron heads) is to machine the head for ½ inch O.D. guides.

The valve stem to guide clearance is then reamed to size using the go-no-go method. Unfortunately, it is not uncommon for a valve guide of this nature to have a very short life span. Here’s why; the machining process that allows the ½ inch guide to be used leaves minute imperfections between the head and guide. These are microscopic air pockets that do not allow heat to transfer from the guide to the water-cooled head. When valve guides over heat, they burn up the oil that lubricates the valve, which causes the valve to gall or seize in the guide. In addition, the crude method of setting up the clearance leaves rough, uneven surfaces inside the valve guide which promote premature valve stem and valve guide wear. By reaming the guides too, the final size is only determined by how sharp the reamer is.

Phosphor Bronze

- High strength-to-weight ratio

- More dense than cast iron

- Higher rate of thermal conductivity

- Lower coefficient of friction

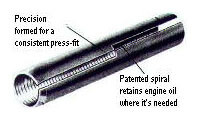

The Bronze Bullet liner takes K-Line Guide-Liner technology to a new dimension by incorporating the proven benefits of phosphor bronze and K-Line’s exclusive Interrupted Spiral and bullet nose.

Interrupted Spiral

Note that the spirated grooves do not align at the seam. The reason Lubrication is suspended in the guide, reducing the possibility of excessive oil pass-through.

At Louthan Competition LLC, we install phosphorous-bronze valve guides, and every guide is honed to an exact dimension based on the valve that is going in that guide. Tolerance is measured with a Sunnen dial bore gauge and is accurate within .0001″ (1/10 of one thousandth of an inch). By fitting the valve guides accurately with a hone and a dial bore gauge, oil consumption is better controlled and longevity is increased by many times due to smoother wear surfaces and increased surface area for better heat-transfer. The good news is that our prices are very competitive, so you won’t pay extra to get a lot more!

Contact Us

From Stock Restoration to Race Only applications, I can improve and maximize the efficiency of any cylinder head, stock or aftermarket. Achieve increased horsepower and improved fuel economy. I have experience with virtually all makes and brands.

Valve Job

The valve seat has three purposes: to seal the port, to cool the valve, and to guide the air through the valve opening. So, you can see why the quality of the valve job is crucial to the performance of your cylinder head. Great caution is taken when cutting a valve seat.

First, to insure there is no run out (or mis-alignment) between the valve guide and the valve seat. Second, to position the seat with the valve regarding angle, diameter, and width. By eliminating run out, the valve will seat properly without unnecessary side load on the valve guide. Every valve job features multi angles; at least three on the seat and two on the valve.

In addition, the area where the seat contacts the valve is positioned on the very outside diameter of the valve.

For example, dis-assemble a stock 350 Chevrolet head. There is a 1.5 inch exhaust valve, but the area where the seat contacts the valve face is anywhere from the extreme inside diameter to the middle of the valve face. What is the point of using a 1.5 inch valve if you’re only going to cut a 1.4 inch seat? By positioning the seat to the outside and using multiple angles, you will gain several cfm in air flow even on un-ported heads with stock sized valves.

Surfacing

There are many shops that are still using a 50 year-old surfacing broach. Although they may produce a flat surface, it is often so coarse that the head gaskets must be coated with aluminum or copper paint upon installation to prevent coolant from seeping out between the head and block. As a result, most shops resort to using wet surface grinders.

The main disadvantage of this is that the grinding stone breaks down as it grinds, causing less material to be removed from the head surface as the stone traverses across it. The wet surface grinder does produce a very smooth surface, but did you know it is possible to have too smooth a surface on a head or block deck?

The majority of the import engines today, as well as many domestics, are using aluminum heads on iron blocks. The expansion rate of these two metals is nearly a 2:1 ratio, so as the temperature increases the head expands at twice the rate of the block. This makes the surface finish critical to prevent head gasket failure. Surface finish is measured in Ra (roughness average) or in minch (micro inch) with a digital profilometer. If it’s too smooth the gasket will not grip the surface and it may blow out. If it’s not smooth enough it will actually “work” back and forth with the unevenly expanding metals until it tears and eventually blows out.

To produce the highest quality finish with the most accuracy, we utilize a Storm-Vulcan wet grind surfacer converted to a state-of-the-art dry CBN cutter. The traverse on the machine is hydraulic, so feed rate is infinitely adjustable. This makes it possible to tailor the finish to each specific cylinder head.

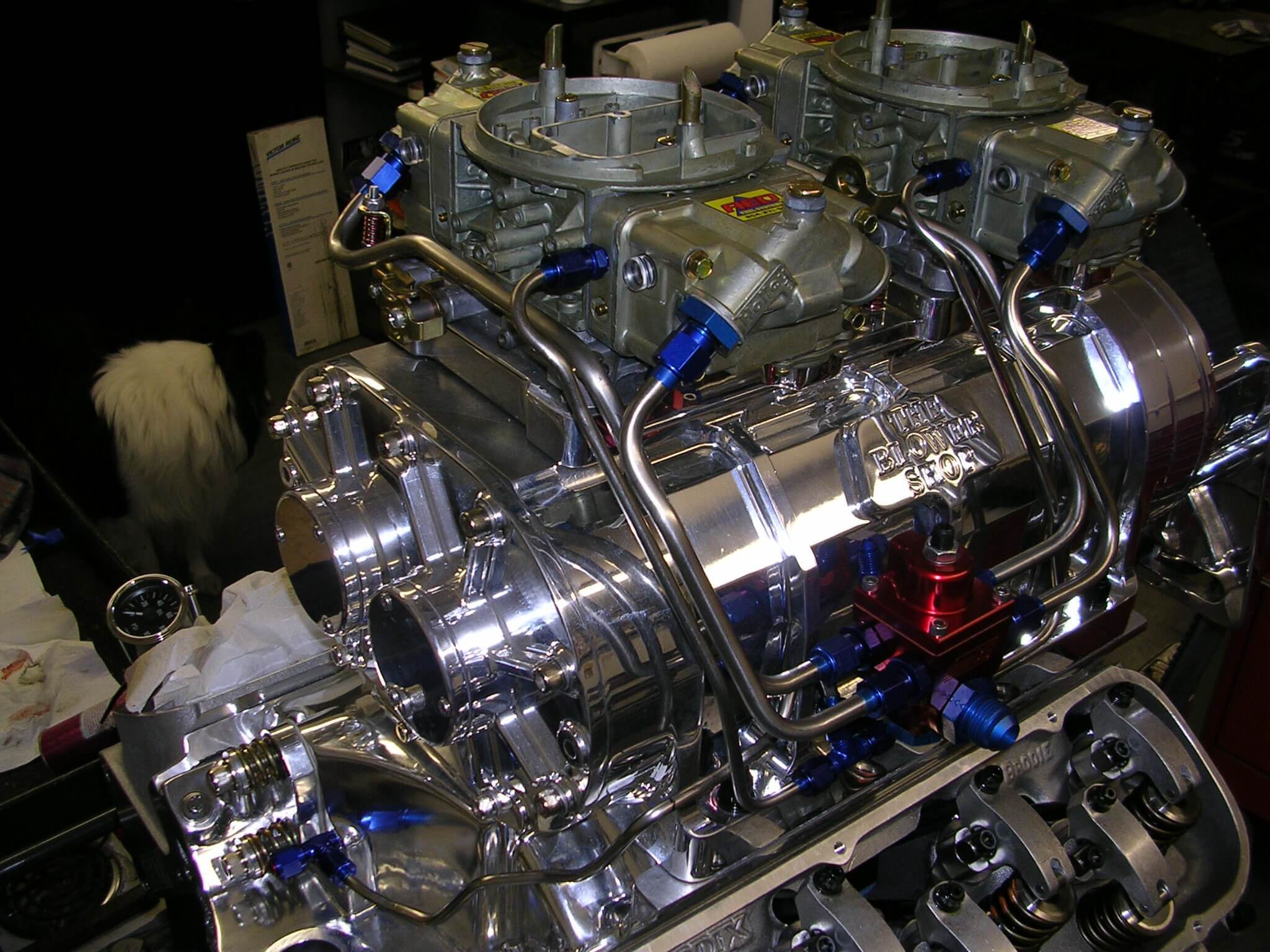

Carburetors

Here’s some interesting information about carburetor flow statistics.

Presently, most carburetors are rated in flow capacity at a test pressure of 20.4 inches of water, which is 1.5 inches of mercury. Therefore an 850 cfm carb is one that flows 850 cfm at 20.4 inches of water. If you’ve ever watched a vacuum gauge on a performance engine at full throttle, you know it reads about .5 inches of mercury or 7.8 inches of water.

So, testing the same carburetor at a pressure drop of 7.8 inches of water, the 850 now flows a mere 490 cfm. This is why carburetor ratings seem to be out of proportion to engine requirements.